|

Author: Dr Conor O'Brien, Senior Technology Analyst at IDTechEx

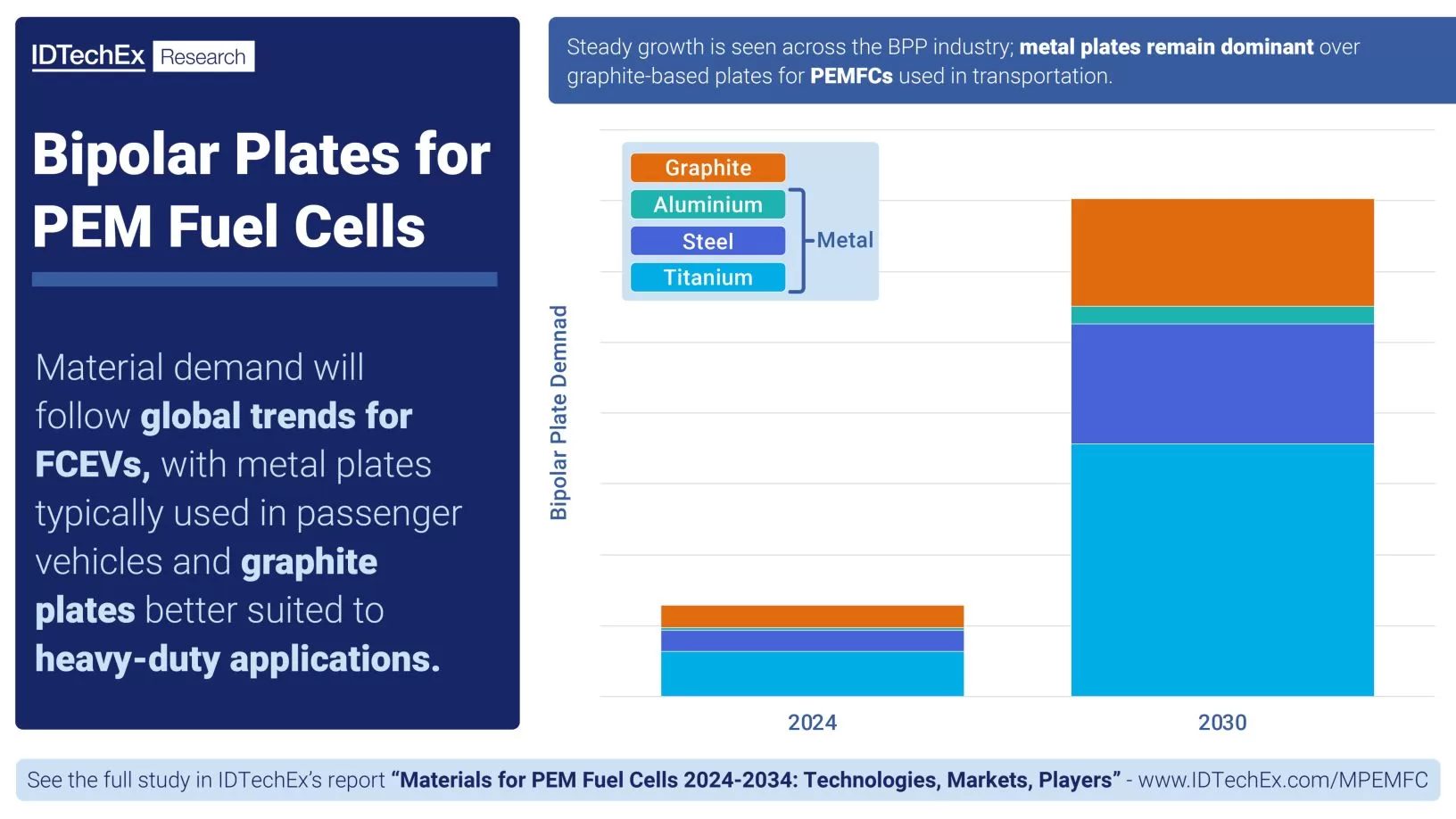

Bipolar plates are crucial components in proton exchange fuel cells, representing a substantial portion of the value of the fuel cell stack. IDTechEx predicts that their market value will surpass US$2.5 billion by 2034. The choice between metal and graphite materials for bipolar plates is a significant consideration, with each option having distinct advantages depending on the specific application. Whether considering compact passenger cars or heavy-duty applications, such as marine, trends are emerging for the dominant bipolar plate material in each sector for PEM fuel cells.

The IDTechEx report, “Materials for PEM Fuel Cells 2024-2034: Technologies, Markets, Players“, provides a comprehensive technical overview of bipolar plates and other key components for PEM fuel cells, an assessment of the major providers of bipolar plates, and also includes granular 10-year market forecasts for key fuel cell components and materials in terms of both units and volume.

Bipolar plates (BPPs) fulfill a number of vital roles within fuel cells, serving not only as structural support and a current collector but also as a barrier between the oxygen and hydrogen gases. Choosing the appropriate material for these plates involves considering several parameters including mechanical strength, corrosion resistance, electrical and thermal conductivity, as well as material costs. IDTechEx's report benchmarks graphite and metal BPPs, the primary material options, offering comprehensive analysis of component suppliers, manufacturing processes, and supply chain agreements with OEMs.

The effectiveness of gas distribution within the fuel cell relies heavily on the design of the channels, or flow field, in the BPPs. A key consideration in BPP development revolves around selecting the most suitable method for creating these channels within the plate. Machining, typically performed using computer-guided CNC machines, involves mechanically removing material to shape the flow field. However, challenges arise during post-fabrication processes, such as the removal of unwanted burrs and the need for a complex coating process, leading to fewer manufacturers opting for this method. On the other hand, stamping, also known as compression molding for graphite-based plates, remains the predominant method for BPP formation. Coatings can be applied prior to stamping, but caution is necessary to avoid introducing defects that could lead to pinhole corrosion of the plate. Laser welding is utilized to seal any gaskets or other components to the BPP. |

|

|

|

|

||

|

Bipolar Plates for PEM Fuel Cells. Source IDTechEx |

||

|

For heavy-duty PEM fuel cell applications, such as trucks, trains and ships, the form factor and energy density of the fuel cell stack is not of primary concern, with the cost of the plates taking priority. For this reason, graphite and graphite-based composite plates are better suited to the heavy-duty applications. For passenger cars in particular, the form factor and energy density of the fuel cell stack is of paramount importance and so metal bipolar plates dominate in this sector and for similar applications such as in light commercial vehicles or vans. Early movers in this space are Toyota and Hyundai, with these OEMs utilizing titanium and steel plates, respectively. As coating technologies improve, both in terms of material development and reducing coating defects, it is expected that other metals, such as aluminum, will become viable alternatives to titanium and steel, helping to reduce the weight of the cell further and, therefore, increase the energy density of the stack.

Beyond stamping and machining, alternative production methods are beginning to emerge for BPPs that could shift the narrative away from material choice towards these novel solutions. Etching, including both photochemical and laser methods, presents a novel approach to producing BPPs, drawing from techniques utilized in the semiconductor components industry. However, for metallic BPPs, a complex coating process is essential to prevent corrosion, while etching is not well suited to graphite plates. Sticking with processes traditionally seen in the semiconductor industry, Bramble Engineering is developing a unique production technique for BPPs, leveraging printed circuit board technology with plans to license the technology to OEMs following proof of scalability. Despite these emerging alternatives, IDTechEx predicts that traditional manufacturing techniques will continue to dominate the market in the mid-term, retaining a significant market share in the long run.

For more details on the materials demand, trends, and emerging novel alternatives to the incumbents for PEM fuel cells, see the IDTechEx market report “Materials for PEM Fuel Cells 2024-2034: Technologies, Markets, Players”.

Find out more about this report. Including downloadable sample pages, at www.IDTechEx.com/MPEMFC.

For the full portfolio of market research from IDTechEx, please visit www.IDTechEx.com. |